How Premier Aluminum Llc can Save You Time, Stress, and Money.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Blog Article

The 8-Minute Rule for Premier Aluminum Llc

Table of ContentsExamine This Report on Premier Aluminum Llc6 Simple Techniques For Premier Aluminum LlcPremier Aluminum Llc Fundamentals ExplainedPremier Aluminum Llc Can Be Fun For Everyone

(https://www.awwwards.com/premieraluminum/)Traditionally, a buyer's primary responsibility was to find certified and responsive suppliers. Sometimes, purchasers presumed that any distributor happy to contractually fulfill the purchase demand was certified. However, making use of inexpensive and unqualified suppliers can trigger top quality problems, and lost time and cash in the future. To assist you via the procedure, here are some points to consider when choosing the ideal steel casting vendor.

For instance, a firm that only utilizes the financial investment spreading procedure will try to sell you on why that process is best for your application. Yet suppose using the sand casting process is best for you and your requirements? Rather, try to find a vendor that supplies a variety of casting procedures so the very best alternative for YOU is picked

If working with a solitary resource for all of your casting requires is very important to you, the supplier requires to be diverse in its capabilities. When combined with various other integrated abilities, this can help streamline and press the supply base. When choosing the right spreading distributor, cautious consideration ought to be provided to top quality, solution, and cost.

The 6-Second Trick For Premier Aluminum Llc

Purchasers significantly pick casting distributors that have machining abilities. This can prevent conflict if flaws are uncovered during machining. If a 3rd party is machining, it may result in "finger-pointing" concerning that is at fault. Is it a casting issue or a machining concern? If the spreading provider finds an issue throughout machining, the problem is fixed quicker with no dispute over whose mistake it is.

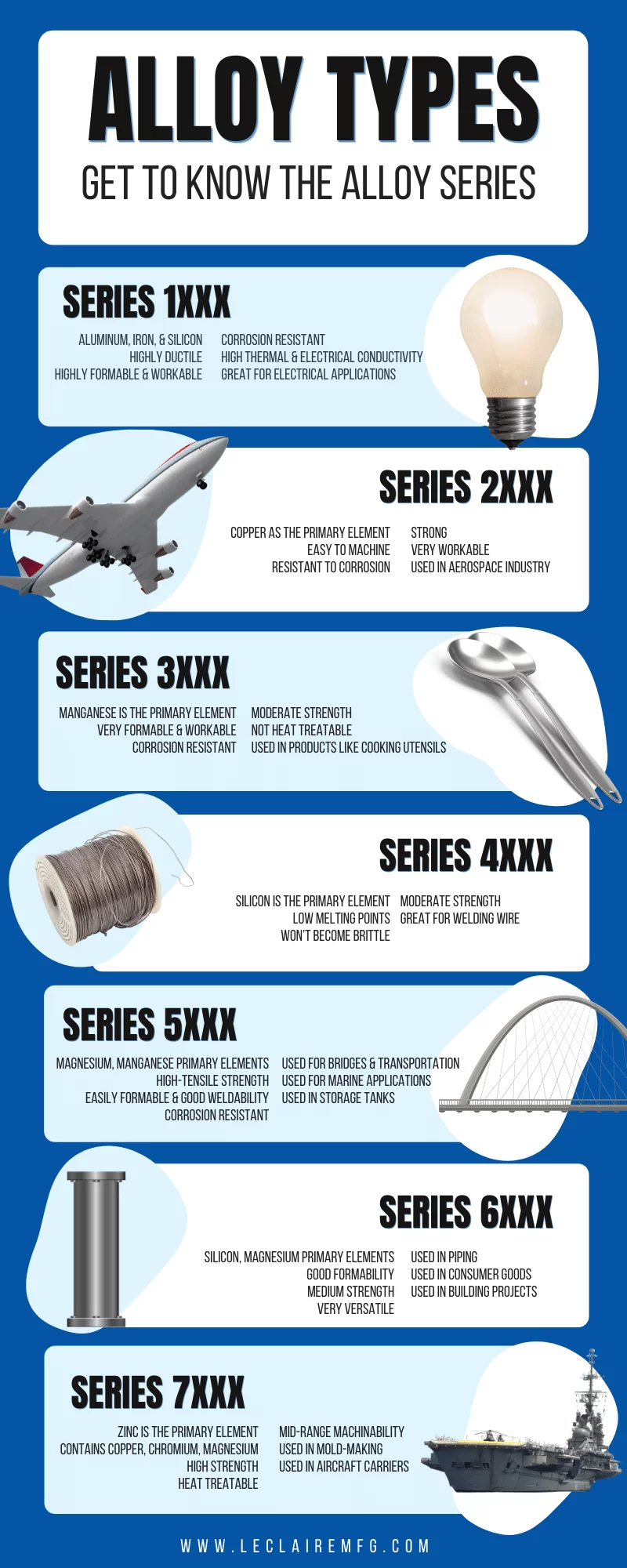

Issue or no, integrated machining streamlines the supply chain and lowers taking care of time and shipping expense prior to the product makes it to the consumer. What do you need from your spreading provider? Are you searching for someone to just provide a steel part to your front door or do you need more? If you do not have internal metallurgy experience, validate that the supplier can offer support in choosing the correct alloy based on your details application.

Some foundries are limited or specialized. Make get redirected here sure the vendor can meet all your material or alloy requirements to eliminate the requirement for several suppliers.

Premier Aluminum Llc Can Be Fun For Everyone

Study the distributor's web site. Speak with a sales rep or organization affiliate. Ask a great deal of inquiries. See their facility. Obtain an understanding of what they can do for you and if you can see yourself constructing a strong, common relationship with them.

Aluminum is likewise light-weight and has great rust resistance, making it ideal for applications where weight and toughness are vital variables. In addition, aluminum spreading is a cost-efficient approach of production, as it requires less power and resources than various other approaches. Iron casting, on the other hand, entails putting molten iron right into a mold and mildew to develop a preferred shape.

What Does Premier Aluminum Llc Do?

Iron spreading is likewise able to hold up against heats, making it ideal for use in applications such as engine parts and industrial machinery. Iron casting can be much more expensive than light weight aluminum spreading due to the greater cost of raw materials and the energy called for to melt the iron. When determining in between aluminum spreading and iron casting, it is very important to consider the certain requirements of the application.

In final thought, both aluminum spreading and iron spreading have their own distinct advantages and disadvantages. There are 3 sub-processes that fall under the classification of die spreading: gravity die casting (or permanent mold spreading), low-pressure die casting and high-pressure die spreading. To get to the completed product, there are 3 key alloys used as die spreading material to choose from: zinc, light weight aluminum and magnesium. Report this page